NYU Tandon team advances to the American Made Challenges “E-Robot” phase II competition

Their solution for reducing leak- and moisture-related energy costs in buildings sits squarely at the intersection of robotics, 3D models, and sustainability.

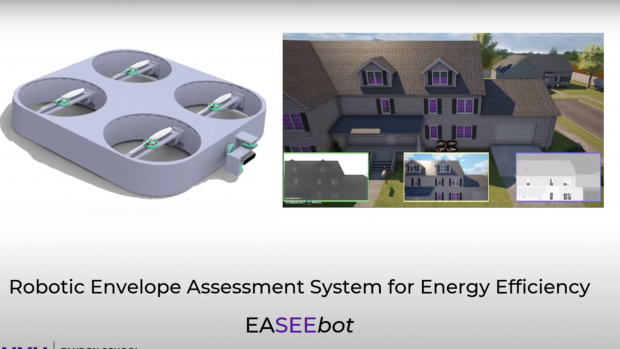

EASEEbot will safely and noninvasively fly around a structure, auto-generating a 3D model using advanced computer vision and AI techniques. It recently won a $200,000 cash prize to be used for prototyping and testing.

Most people go about their day never giving much thought to their home or office building’s “envelope” — a term that encompasses elements such as walls, doors, windows, roofs, foundations, and siding that mark the separation of the interior and exterior of a structure. When a building’s envelope is sound, heated or cooled air is kept in, and damaging moisture is kept out.

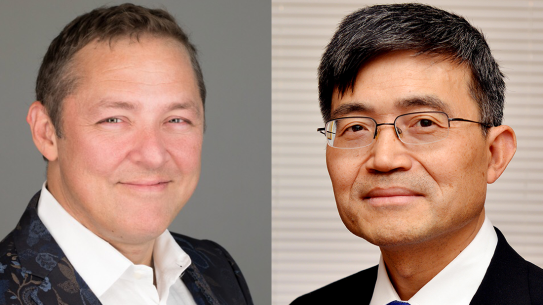

Unfortunately, as Associate Professor Semiha Ergan of Tandon’s Building Informatics and Visualization Lab (BILab) and Professor Chen Feng of the Automation and Intelligence for Civil Engineering (AI4CE) Lab point out, America is currently facing a “leaky” building epidemic. Annually, building owners spend more than $42 billion on leak- and moisture-related energy costs–a figure that does not even take into account the toll associated with shorter envelope life cycle, lost rent, and, in some cases, litigation.

To fix leaks, Chen and Ergan explain, it’s first necessary to find them, but current methods can be intrusive, expensive, and potentially hazardous to worker safety. The two recently convened a group of their graduate students to devise an innovative solution: EASEEbot (Envelope Assessment System for Energy Efficiency).

EASEEbot will safely and noninvasively fly around a structure, auto-generating a 3D model using advanced computer vision and AI techniques. The drone will also be able to scale buildings and use long-wave radar and machine learning to detect hidden deep moisture penetration and other major defects.

Last month, their team — which includes Dan Lu, a doctoral candidate in the Department of Civil and Urban Engineering and member of the BILab; Xuchu Xu, a doctoral candidate in the Department of Mechanical and Aerospace Engineering and a member of AI4CE; and Bilal Sher, a civil and urban engineering master’s student and member of AI4CE, along with Sunglyoung Kim and Abhishek Rathod — faced off against almost 400 other innovators during the American Made Challenges “E-Robot” (Envelope Retrofit Opportunities for Building Optimization Technologies) competition.

As one of only ten finalists chosen in Phase 1 of the competition, which is aimed at advancing American leadership in the energy marketplace, EASEEbot earned its developers a $200,000 cash prize to be used for prototyping and testing, along with a chance to win part of the $2 million Phase II prize pool. (Some of that testing will be done right here on campus thanks to the cooperation of NYU’s Buildings and Facilities department.)

“We couldn’t be prouder of the EASEEbot team,” NYU Tandon Dean Jelena Kovačević said. “Their work, which involves robotics, AI-based data analysis and mapping, augmented reality, and sustainability studies, truly shows the power of multidisciplinary collaboration. At Tandon, we like to say we’re educating unconventional engineers, and the team’s creativity and outside-the-box thinking — or should I say in this case ‘outside-the-envelope’ thinking — are great examples of that.”